ItemPick¶

This tutorial shows how to use the ItemPick module with Roboception’s URCap.

Before we start¶

This tutorial assumes that the tutorial Getting started with ItemPick has been completed, and that a valid hand eye calibration has been stored on the rc_visard as described in Hand-eye calibration.

Overview¶

The ItemPick functionality is available in the generic rc_visard node. Please see Generic rc_visard node in order to learn how to work with generic rc_visard nodes.

The following functions are available for ItemPick:

- ComputeGrasps: Triggers grasp computation

- GetNextGrasp: Gets the next grasp after detection has been triggered

- GetLCPose: Returns the pose of the detected load carrier.

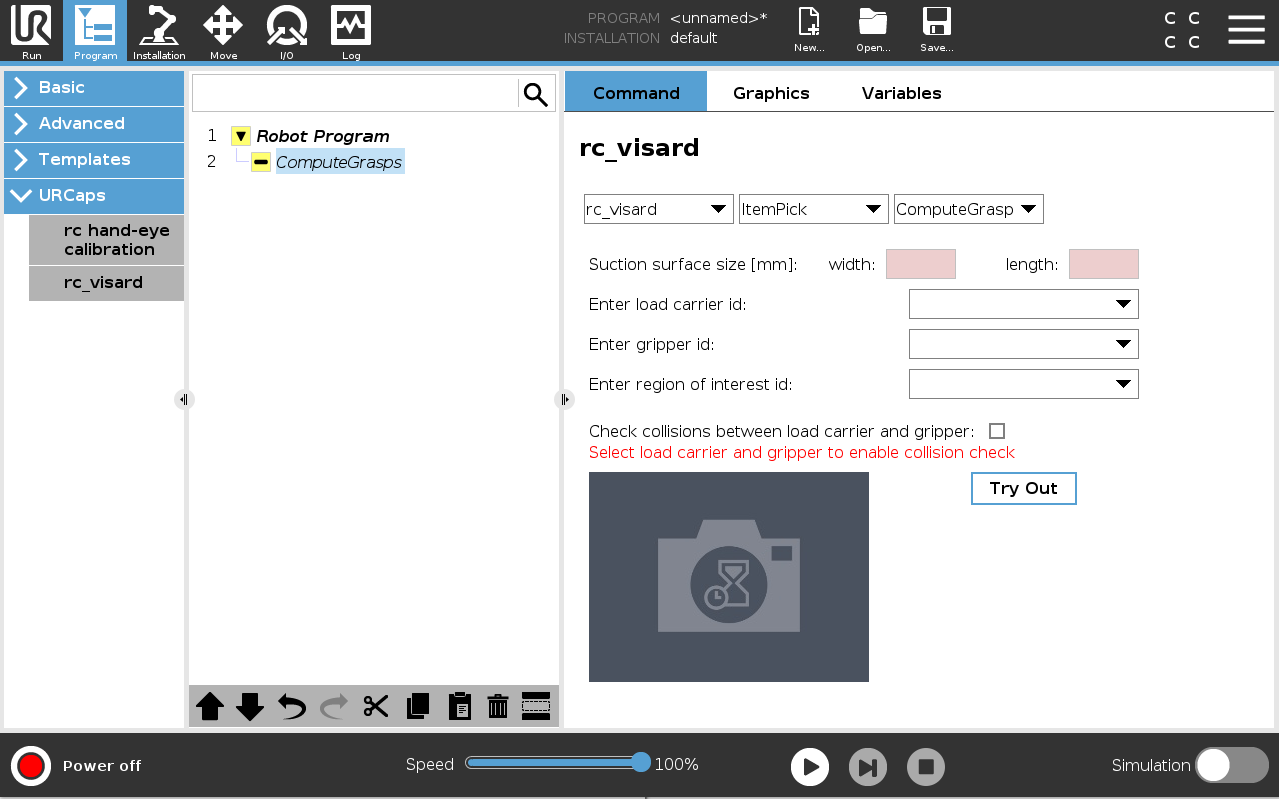

ComputeGrasps¶

It is mandatory to set the minimum and maximum length and width of the suction cup. If necessary, enter a load carrier ID and/or a region of interest ID.

If the CollisionCheck license is available on the sensor, it is also possible to set the gripper and pre-grasp offset for the collision check.

Note

The region of interest and load carrier have to be defined in the Web GUI of the sensor. Only the regions of interest defined in ‘external’ frame are shown in the URCap.

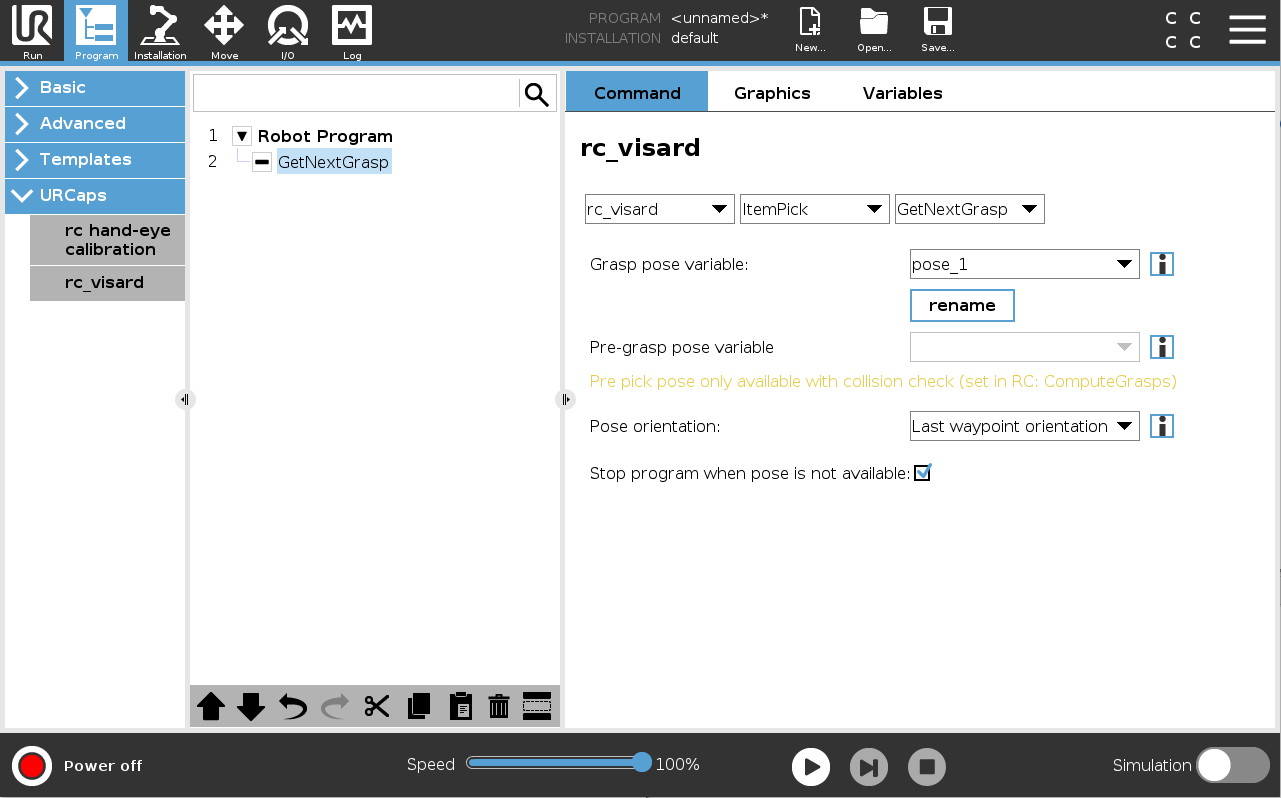

GetNextGrasp¶

This function requires that the ComputeGrasps has been triggered before. It assigns the next available grasp pose and stores the pose in PolyScope’s variable format (e.g. p[-0.300517, -0.367119, -0.007997, -0.001221, 3.116277, 0.038892]).

If no reachable grasp is detected and the Stop program when pose is not available checkbox is checked, a popup will appear and the program will be terminated. If the checkbox is not checked, a zero pose (p[0,0,0,0,0,0]) will be returned.

Note

When the Stop program when pose is not available checkbox is unchecked, the user has to catch the case when nothing is detected (the zero pose (p[0,0,0,0,0,0]) is returned). If this situation is not handled, it might lead to collision or undefined robot behavior.

With the ‘Pose orientation’ drop-down menu it is possible to change the strategy of calculating the angle of the returned pose. There are four different options to choose from:

- Last waypoint orientation The detected orientation is ignored, instead the orientation of the last waypoint is used.

- Only RZ from detected pose For RZ the detected orientation is used, RX and RY are based on the last waypoint orientation.

- Only RX, RY from detected pose For RX and RY the detected orientation is used, RZ is based on the last waypoint orientation.

- Detected pose orientation The complete detected orientation is used.

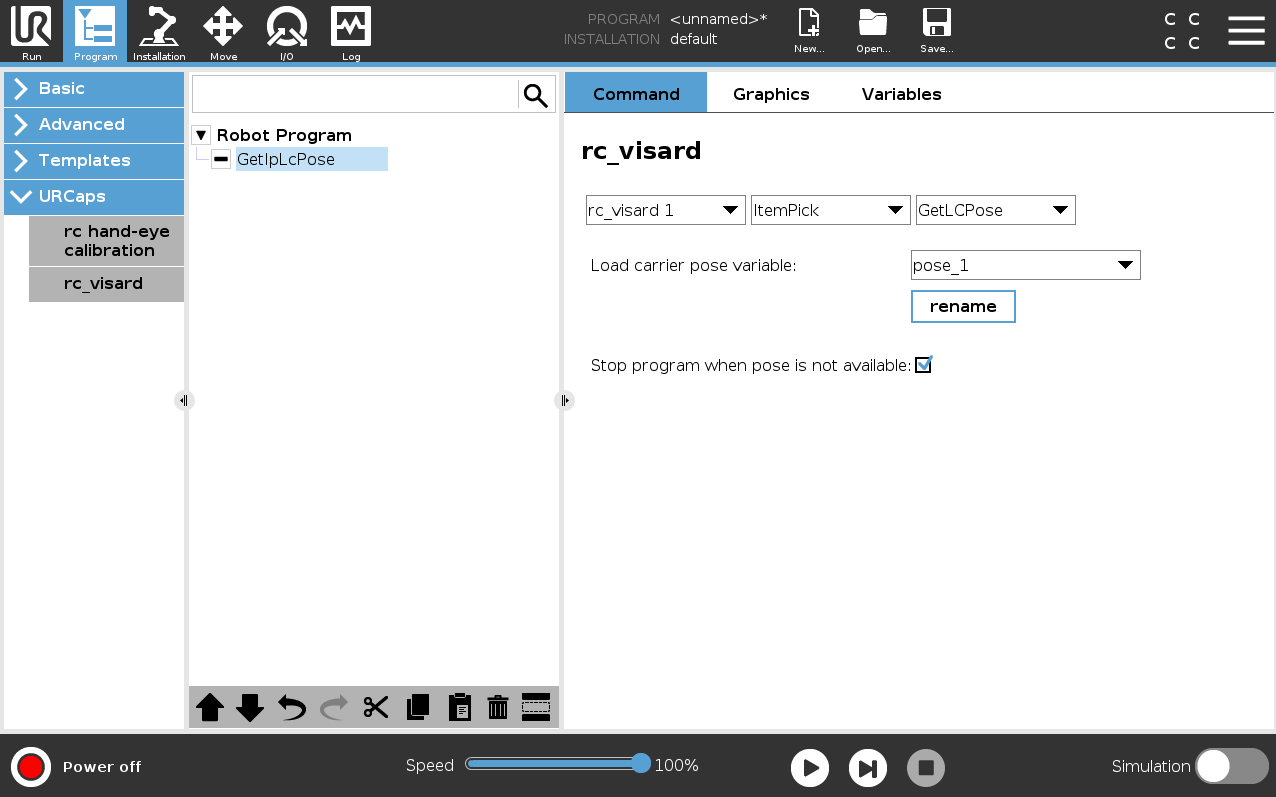

GetIpLcPose¶

This function requires that ComputeGrasps has been triggered with a load carrier ID. It returns the pose of the detected load carrier. If no load carrier is detected, a zero pose (p[0,0,0,0,0,0]) will be returned.

Note

When the Stop program when pose is not available checkbox is unchecked, the user has to catch the case when nothing is detected (the zero pose (p[0,0,0,0,0,0]) is returned). If this situation is not handled, it might lead to collision or undefined robot behavior.